Material Selection for Curtain Walls: A Balance of Performance and Aesthetics

As a key part of a building’s exterior façade, curtain walls impact both visual appeal and essential functions such as insulation, thermal performance, wind resistance, soundproofing, and fire protection. Choosing the right materials for a curtain wall involves a comprehensive assessment based on architectural style, climate conditions, usage scenarios, and cost considerations. This guide analyzes mainstream materials, their performance characteristics, and suitable applications to help define what makes “good” curtain wall materials. Ultimately, the choice of materials should align with the project requirements — whether prioritizing structural stability or cost-effectiveness — to ensure a more durable and longer-lasting façade.

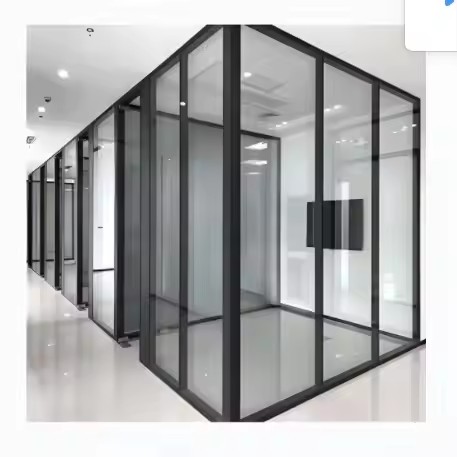

- Glass Curtain Walls: A Balance of Transparency and Energy Efficiency

Glass is one of the most commonly used curtain wall materials. Its modern and transparent aesthetic makes it ideal for commercial buildings and office towers. Key performance factors include light transmittance, thermal insulation, safety, and impact resistance. Glass curtain walls allow occupants to enjoy outside views, offering visual relief and a moment of calm for people working in high-rise buildings.

Low-Iron (Ultra-Clear) Glass:

With an iron content of ≤0.015%, low-iron glass offers light transmittance of over 91%, minimizing the green tint seen in regular glass and giving the façade a cleaner appearance. When paired with Low-E (low emissivity) coatings, it reflects infrared radiation and reduces heat buildup indoors. It’s particularly suitable for tropical or hot regions, providing both daylighting and energy efficiency.

Laminated Glass:

Made by sandwiching PVB film between two or more glass sheets under high temperature and pressure, laminated glass doesn’t shatter upon breakage, making it extremely safe. It’s ideal for high-rise buildings and high-traffic areas like shopping malls and hotel podiums. It also offers sound insulation (approx. 30–40 dB).

Vacuum Glass:

Formed by creating a vacuum between two glass panes, this type offers far superior insulation compared to regular double glazing (U-value as low as 0.4 W/m²·K), making it suitable for cold climates. However, it is expensive and requires precise installation to prevent seal failure at the edges.

- Metal Panels: Combining Strength and Visual Texture

Metal curtain walls are widely used in modern architecture due to their durability and flexibility. Common choices include aluminum panels, titanium-zinc panels, and copper panels.

Aluminum Panels:

Typically made of 1–3 mm thick aluminum alloy sheets, these panels are processed through bending and coating. Surface treatments include fluorocarbon paint (high weather resistance, over 20 years lifespan) or powder coating (vivid colors, lower cost). Aluminum panels are lightweight (~2.7 kg/m²) and strong, suitable for large-span façades like airports and stadiums. However, they lack good insulation and must be paired with thermal layers.

Titanium-Zinc Panels:

Made primarily of zinc with added titanium and copper, these panels naturally develop a protective patina (“zinc bloom”) that creates a uniform blue-gray tone over time, adding a vintage touch. They offer excellent corrosion resistance and can last over 50 years. Suitable for historic renovations or nature-inspired architecture, though they are costly — about 3–4 times the price of aluminum panels.

Aluminum Honeycomb Panels:

Consist of two aluminum sheets sandwiching a honeycomb core, making them lightweight, stiff, and better at insulating against sound and heat (sound insulation up to 40 dB). Ideal for large, flat surfaces like museums or theaters. However, complex manufacturing makes them expensive.

- Stone Curtain Walls: Natural Texture and Longevity

Natural stones like granite and marble add weight, texture, and a cultural or luxurious feel to buildings, making them ideal for high-end or iconic projects.

Granite:

With high hardness (Mohs 6–7) and strong weather resistance, granite is ideal for exterior façades like office buildings or hotels. Common types include Sesame Black or Yellow Rust Stone. Surface finishes include flamed (non-slip) or polished (reflective — care must be taken to avoid light pollution). Due to its weight (~28 kg/m²), dry-hanging systems with metal anchors are required for safe installation. It is relatively costly (RMB 300–800/m²).

Marble:

Known for its rich textures (e.g., Carrara White, Jazz White), marble has lower hardness (Mohs 3–5) and is vulnerable to acid rain. It’s best for interior walls or use in mild climates. Proper waterproofing is essential to prevent staining from water absorption.

Artificial Stone:

Made by compressing natural stone powder with resin, artificial stone offers uniform color and lower cost. It’s less likely to crack but has weaker weather resistance, making it better suited for interior walls or mid- to low-end projects.

- Auxiliary Materials: Critical for Overall Performance

The success of a curtain wall system doesn’t rely solely on primary materials — auxiliary materials like sealants, profiles, and insulation layers are just as essential:

Sealants:

Use high-durability silicone sealants (lifespan ≥20 years) rather than basic glass glues, which tend to crack and leak over time. For structural glazing systems (e.g., hidden frame curtain walls), structural silicone must meet national standards for load-bearing performance.