I. Mature Industrial Clusters Creating a Full-Chain Advantage

China’s sliding door manufacturing industry has developed a complete ecosystem — from raw material supply to finished product delivery — with highly efficient industrial clusters. Key production hubs such as Foshan (Guangdong), Shaoxing (Zhejiang), and Linqu (Shandong) concentrate enterprises in aluminum extrusion, glass processing, hardware accessories, and door assembly, forming an integrated “1-hour supply chain circle.”

This clustering model delivers three key advantages:

Fast Supply Chain Response –

Raw materials and components can be sourced and coordinated on the same day, greatly shortening production lead time. For example, the process from aluminum extrusion mold opening to final assembly can be completed within 7–10 days, compared to 20–30 days for most overseas manufacturers.

Lower Resource Integration Costs –

Clustered enterprises share logistics, warehousing, and testing infrastructure, reducing material procurement and operational costs by 15–20% compared with dispersed production models.

Strong Technological Synergy –

Frequent collaboration between upstream and downstream companies drives rapid innovation. For instance, glass manufacturers and door producers co-develop Low-E energy-saving glass + sealed aluminum profiles, improving insulation and thermal performance for sliding door applications.

II. Rapid Technological Upgrades Bringing Products to Global Standards

Through continuous R&D investment, Chinese sliding door manufacturers have shed the outdated “low-cost, low-quality” stereotype and achieved technological parity — and in some areas, leadership — with international brands.

Upgraded Material Technologies –

Manufacturers now use 6063-T5 high-grade aluminum alloy, offering 30% higher strength than standard aluminum, and employ electrophoresis or powder coating for corrosion and weather resistance (operating range: –30°C to 70°C).

Glass options include tempered, laminated, and argon-filled insulated glass, meeting multi-functional demands such as soundproofing (up to 42 dB), bullet resistance, and energy efficiency.

Smart Manufacturing Systems –

Leading enterprises utilize advanced German HOMAG CNC production lines and fully automated glass cutting systems, achieving cutting precision of ±0.1 mm and assembly tolerance ≤ 0.5 mm. Product qualification rates exceed 99%, far above the industry average.

Innovative Functional Designs –

Tailored solutions for different use scenarios include:

Balcony Sliding Doors: Featuring maglev tracks and anti-drop designs for silent operation (≤35 dB) and smooth sliding, with wind pressure resistance up to 5000 Pa for coastal regions.

Interior Partition Doors: “Fluted glass + ultra-narrow frames” balance transparency and privacy, aligning with modern minimalist aesthetics.

Industrial Sliding Doors: Reinforced profiles and heavy-duty hardware enable load-bearing capacity above 500 kg, ideal for factories and warehouses.

III. Superior Cost Control Delivering Outstanding Value

Leveraging economies of scale and supply chain efficiency, Chinese manufacturers maintain unbeatable cost-performance advantages:

Economies of Scale –

Leading factories produce over 1 million sets per year, lowering unit manufacturing costs by 25–30% through bulk raw material purchasing and standardized processes.

For example, a standard aluminum sliding door (2m × 2.4m) from China can cost 40–50% less than a comparable European product — while maintaining equivalent structural and performance specifications.

Flexible Production Balancing Customization and Cost –

Modular design divides doors into three major components — frame profiles, glass, and hardware — enabling mass production of standard parts while allowing fast configuration for customization (special dimensions, colors, or functions).

The customization premium is typically only 10–15% above standard models, far lower than the 30%+ markup common among foreign brands.

End-to-End Cost Optimization –

From long-term contracts with aluminum suppliers (locking in favorable prices) to optimized international logistics via China–Europe freight trains and fast sea shipping, every stage is cost-efficient — delivering maximum value to global buyers.

IV. Deep Customization Capabilities for Global Market Diversity

Chinese sliding door manufacturers provide comprehensive customization across size, material, function, and application scenarios, meeting varied regional and customer-specific demands worldwide.

Regional Adaptation –

North America: Products meeting ASTM standards, with profile thickness ≥ 1.8 mm, designed for hurricane-prone regions.

Europe: CE-certified energy-efficient doors, with heat transfer coefficient (U-value) as low as 1.8 W/(㎡·K), compliant with EU environmental regulations.

Southeast Asia: Moisture-resistant frames and insect-proof mesh designs suited for hot and humid climates.

Scenario-Based Solutions –

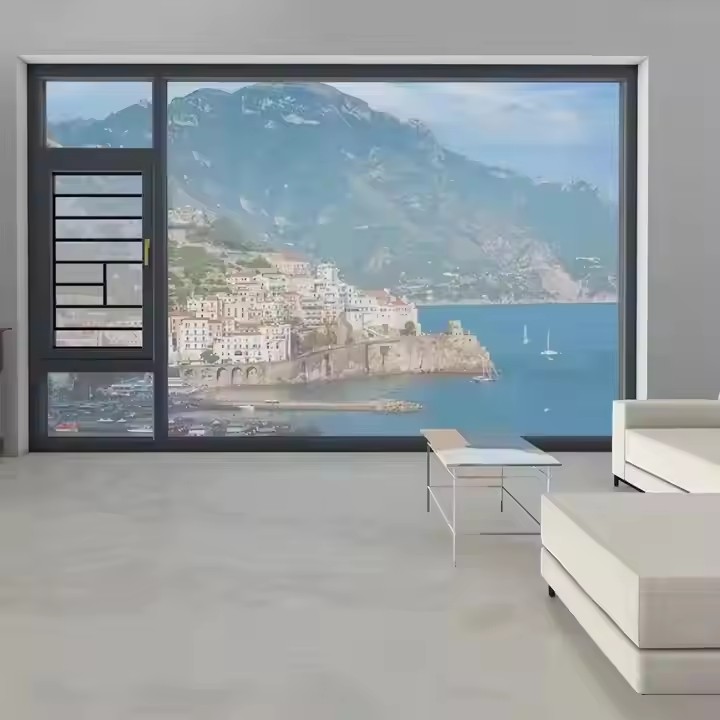

High-End Residences: Smart sliding doors supporting APP control, fingerprint unlocking, and obstacle rebound protection (anti-pinch).

Commercial Spaces & Hotels: Heavy-duty sliding doors with panel widths up to 3 meters, ideal for large open spaces.

Clean Rooms: Airtight sliding doors with IP65 sealing, preventing dust penetration.

Fast Response to Custom Orders –

Through digital order management systems, customers can submit specifications online and receive design proposals and quotations within 24 hours.

The full production cycle is controlled within 15 days, far shorter than the 30+ days typical of overseas brands.