I. Glass Materials: The Core of Energy Efficiency and Safety

Glass accounts for more than 80% of a floor-to-ceiling window’s surface area, and its performance directly determines thermal insulation, safety, and service life. Products should prioritise compliance with AS/NZS 4666 (Insulating Glass Units) and AS/NZS 3538 (Energy-Efficient Glass) standards.

- Glass Structure: Insulating Glass as the First Choice; Triple Glazing for Extreme Climates

Double Glazed Low-E IGU:

The mainstream option in Australia. It consists of two panes of toughened glass with a 12–16 mm air cavity filled with argon or krypton, combined with a Low-E (low-emissivity) coating. Key advantages:

Excellent thermal insulation: Low-E coating reflects over 90% of infrared radiation, blocking outdoor heat in summer and retaining warmth in winter. It meets MEPS (Minimum Energy Performance Standards) and can reduce air-conditioning energy consumption by more than 30%.

Improved acoustic performance: The air cavity effectively weakens traffic and street noise, suitable for CBD or roadside towers.

Balanced cost-performance ratio: Suited for most residential and commercial buildings.

Triple Glazed Low-E IGU:

Designed for extreme climates—cold southern regions (e.g., Melbourne, Adelaide), extremely hot northern regions (e.g., Darwin), or high-wind coastal skyscrapers. Featuring three panes and two cavities, it can achieve a U-value as low as 0.8 W/(㎡·K) and improves sound insulation by about 40% over double glazing. Cost is higher, and weight is heavier, requiring stronger framing systems.

Special Requirements:

- Coastal cities (Sydney, Brisbane): Use “laminated Low-E IGU” with PVB or SGP interlayer to prevent glass fragments from scattering and to resist salt-spray corrosion on the edges.

- High-rise buildings (10+ storeys): Must use “double-toughened laminated glass.” Toughened glass breaks into blunt particles, and the interlayer holds fragments in place to prevent falling hazards. This complies with AS/NZS 1288 (Safety Glass).

- Glass Coatings & Colours: Designed for Australia’s Harsh UV Environment

Low-E Coating Types:

Choose between hard-coat (on-line) and soft-coat (off-line) Low-E. Hard-coat offers superior durability, ideal for single glazing or coastal environments. Soft-coat provides better thermal performance but must be sealed inside IGUs to avoid oxidation.

Double-silver Low-E is recommended—higher visible light transmission (≥70%) and better infrared reflection for balanced daylighting and insulation.

Glass Colour:

Avoid dark tints (black, deep grey), which reduce UV but severely limit indoor natural light, increasing artificial lighting costs. Recommended options: light grey, light bronze, or clear Low-E glass, all capable of blocking 99% of UV radiation—critical in Australia’s world-leading UV conditions to prevent fading of floors and furniture.

Some commercial towers may use ice-blue coated glass for premium aesthetics and reduced glare, fitting modern architectural styles.

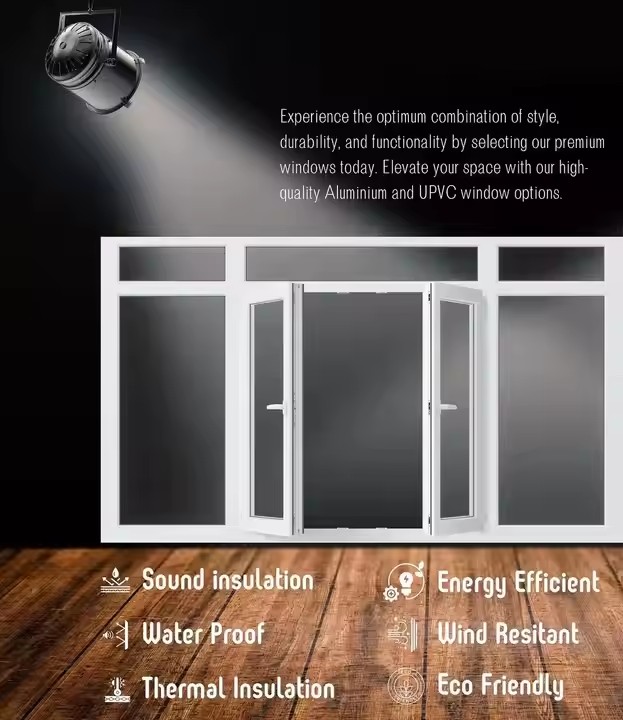

II. Frame Materials: Balancing Durability, Load-Bearing Capacity, and Aesthetics

Frames must withstand Australia’s dry climate (prone to timber cracking) and coastal salt spray (prone to metal corrosion). Mainstream materials include aluminium, solid timber, and aluminium-clad timber, with aluminium being the dominant choice.

- Aluminium Frames: The Mainstream, Balancing Durability and Practicality

Core Advantages:

Aluminium offers excellent corrosion resistance, UV stability, high strength, and light weight, with minimal maintenance—aligned with Australia’s preference for low-maintenance buildings.

Powder-coating or anodising provides strong resistance to coastal salt spray (anodised film ≥15 μm; powder coating ≥60 μm), with service life exceeding 20 years.

Key Selection Criteria:

Profile thickness:

For high-rise buildings (10+ storeys), choose thermally broken aluminium profiles with a wall thickness ≥1.8 mm and a thermal break (PA66 nylon strip) width ≥24 mm to reduce heat transfer and meet NCC (National Construction Code) energy requirements.

Surface treatment:

Coastal areas → PVDF fluorocarbon coating for superior durability and colour stability.

Inland areas → powder coating, offering richer colour options (light grey, white, champagne).

Hardware components:

Select 304 or 316 stainless steel hardware (316 preferred for coastal areas) from quality brands such as Siegenia (Germany) or Doric (Australia).

For panels weighing ≥50 kg, heavy-duty load-bearing hinges are required to ensure smooth operation and structural safety.