Accurately determine the load conditions

Wind load: Calculate according to relevant standards such as the Code for Loads on Building Structures. For curtain walls with a height greater than 200m or those with complex shapes and wind load environments, wind tunnel tests should be carried out to determine the wind load, and the standard value of the wind load should not be less than 1.0kPa. Evaluate the local wind force and then design the curtain wall according to this wind force, including what kind of curtain wall to install.

Gravity load: Consider the self – weight of the curtain wall, including the weight of the panel, skeleton, connection parts, etc., as well as possible additional loads such as maintenance loads. Design the weight in advance, consider how much the maximum load – bearing capacity of the wall is, and the maximum load – bearing capacity that can be achieved, so as to design the curtain wall to ensure safety.

Earthquake action: According to the seismic fortification intensity and site category of the building area, carry out seismic design according to relevant codes to ensure that the curtain wall has sufficient bearing capacity and deformation capacity under earthquake action.

Temperature load: Consider the local temperature change range and the thermal expansion and contraction effect of the curtain wall under different seasons and diurnal temperature differences to prevent structural damage caused by temperature stress. According to the temperature conditions and climate in different regions, it is necessary to ensure that the indoor temperature can be kept constant under certain conditions. Therefore, during the design, it is necessary to ensure the constancy of the temperature and keep the indoor warm. In summer, the indoor should also be kept cool and the leakage of air – conditioning should be reduced to achieve the effect of energy saving.

Reasonably select the structural form

Framed curtain wall: It is suitable for various building heights and shapes. The structural force is clear and the installation is convenient. When the building height is high, the safety can be improved by strengthening the connection of the columns and beams and increasing the support points. According to the specific floor, three – dimensional columns and beams should be used to reinforce the curtain wall to ensure its safety.

Unitized curtain wall: The curtain wall is divided into several unit panels, which are pre – fabricated in the factory and then transported to the site for installation. The unit panels are combined into a whole through reliable connection methods. This type of curtain wall has good sealing performance and high installation efficiency, which can effectively improve the safety and reliability of the curtain wall.

Point – supported curtain wall: The glass and other panels are connected to the support structure through the connecting pieces. It is suitable for the building parts with large – span and good transparency effect. During the design, it is necessary to ensure the strength and connection reliability of the connecting pieces, as well as the stiffness and stability of the support structure.

Strictly select materials

Skeleton materials: Aluminum alloy profiles or steel materials can be selected. The aluminum alloy materials should be treated by surface anodizing, electrophoretic painting, etc.; the steel materials should be treated by hot – dip galvanizing and other anti – corrosion measures to ensure the durability of the curtain wall.

Panel materials: The outer glass of the glass curtain wall should be made of safety laminated glass, etc.; the glass used for the daylighting roof and awning should be made of safety laminated glass synthesized by semi – tempered glass, etc. For the stone curtain wall, the stone with hard texture, high strength and good durability should be selected and necessary protective treatment should be carried out. Metal panels such as aluminum single – plate should have sufficient strength and corrosion resistance.

Connection materials: The structural adhesive, weather – resistant adhesive, etc. should meet the relevant standards and have good bonding performance, weather resistance and anti – aging performance. The hardware accessories such as bolts, screws, hanging pieces, etc. should be made of high – strength and corrosion – resistant materials to ensure the connection is firm and reliable.

Optimize the connection design

Connection between curtain wall and main structure: The curtain wall is reliably connected to the main structure through the embedded parts and connection parts. The embedded parts should be accurately embedded during the construction of the main structure. The strength and stiffness of the connection parts should meet the requirements and be able to adapt to the deformation of the main structure.

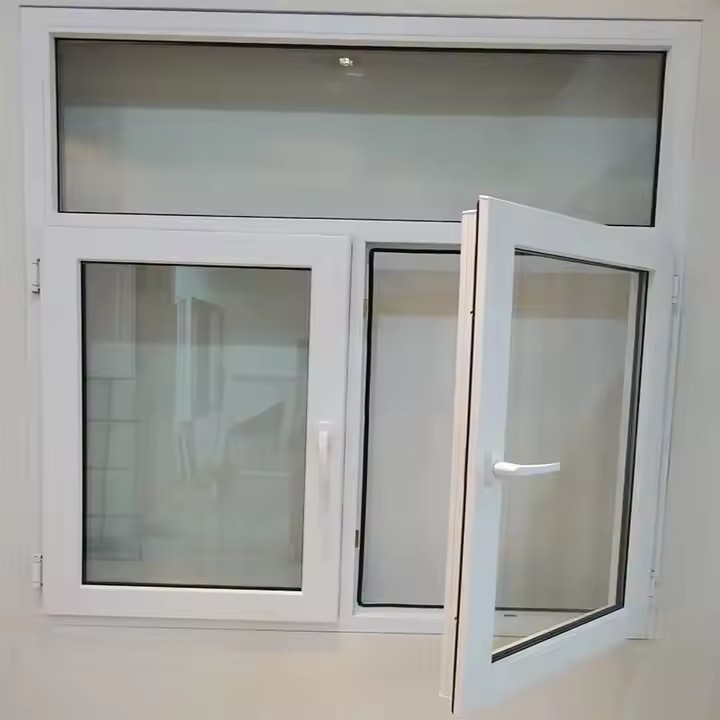

Connection between panel and skeleton: The hidden – frame glass curtain wall should be provided with a support plate, and the support plate is reliably connected to the frame; the corner of the aluminum alloy sub – frame should be reliably connected; the opening window of the curtain wall should be provided with anti – falling measures.

Connection between skeleton components: The connection between the beam and the column should have sufficient strength and stiffness, and can be connected by bolts, welding, etc., and reliable positioning and limiting devices should be set to prevent excessive relative displacement between the components.

Carry out detailed structural analysis and calculation

Static analysis: Calculate the internal force and deformation of the curtain wall under various loads to ensure that the strength, stiffness and stability of the components meet the requirements.

Stability analysis: For high – rise curtain walls, large – span curtain walls or curtain walls with special structural forms, stability analysis should be carried out to prevent the overall or local instability of the structure.

Dynamic analysis: In the seismic design, the response of the curtain wall under the earthquake action is determined through the dynamic analysis, and the seismic construction measures are reasonably designed to improve the seismic performance of the curtain wall.

Pay attention to the detail design and structural treatment

Treatment of deformation joints: The curtain wall panel and its supporting structure should not cross the deformation joint of the main structure. The curtain wall structure corresponding to the deformation joint should be able to adapt to the deformation amount of the main structure.

Fire – proof and lightning – proof design: Set fire – proof isolation belts, fire – proof seals and other fire – proof measures; adopt a reliable lightning – proof grounding system to reliably connect the metal frame of the curtain wall with the lightning – proof device of the main structure.

Drainage design: Design a reasonable drainage system to drain the possible condensate water and rainwater to prevent water from seeping into the curtain wall and affecting the structural safety.